A heat exchanger is like a metal box with a hole in each end in a gas furnace. The first opening brings in an air-fuel mixture that is ignited, producing a flame and heat. The second opening is connected to a pipe that carries the poisonous exhaust gases outside. This is done by using a flue pipe or chimney.

A fan blows air across the metal box, which keeps the box from getting too hot and heats the air distributed through the duct system. You never want the flue gases to get into the airstream because that can make your family sick and even cause death.

The heat exchanger is the most critical component of a furnace, so it is important to maintain it properly. If it gets too hot, it can crack. If it is too cool, moisture can cause it to rust through. When either of these occurs, the exhaust gasses in your system begin mingling with the air circulating through your home, and you begin to breathe potentially dangerous air (like carbon monoxide).

Symptoms of carbon monoxide poisoning are very similar to those of the flu but without a fever. If your family is experiencing headaches, burning eyes or throat, sleepiness, or nausea, and the symptoms improve when you are away from home, you may be experiencing carbon monoxide poisoning.

How Does A Heat Exchanger Work?

It is easy to understand how a heat exchanger works by simply accepting that heat flows from a hot place to a cold place by itself. A heat exchanger does not have to do anything to make the heat go except minimize resistance to the heat flow. This eliminates the need for a heat exchanger to have any moving part of driving the heat flow.

The main part of a heat exchanger is a lot of thin walls of tubes or plates to separate the hot fluid and the cold fluid while allowing heat to pass the wall effectively.

Separate the Fluids but Pass the Heat

A large plate heat exchanger may have hundreds of square feet of walls packed in the heat exchanger. A steam generator may have thousands of tubes; each is about a hundred feet long.

An illustration of how a heat exchanger works is given in this image of a solar energy storage tank. Actually, this simple tank has two heat exchangers.

The bottom heat exchanger passes the heat collected from the solar heat collector to the water in the tank. The top heat exchanger heats the incoming water for use in a shower or elsewhere the heat is needed.

Avoid Fouling

The top heat exchanger can be eliminated by using the tank water directly. The drawback for that is more fouling in the heat exchanger because more water passes the tank.

Water as clean as our drinking water always has some solid in it. This solid will deposit in the tank over time. That may not be a big deal if we can clean the tank periodically.

However, the solid will also deposit on the heat exchanger tube over time, reducing the heat flow. Solid deposition inside the heat exchanger tube is less of a problem because the rushing water will flush the solid out.

Prevent Heat Loss

On the opposite hand, reducing fouling to facilitate heat flow requires building barriers to stop heat flow. This tank has insulation around it to prevent the heat collected from the sun from being lost.

Insulation materials are poor heat conductors. It is hard to make solid heat insulators. Most insulation materials are thin fibers. The fibers may not be as a good insulators as the air trapped among the fibers. If not moving, the air is a very good heat insulator.

Optimize Construction

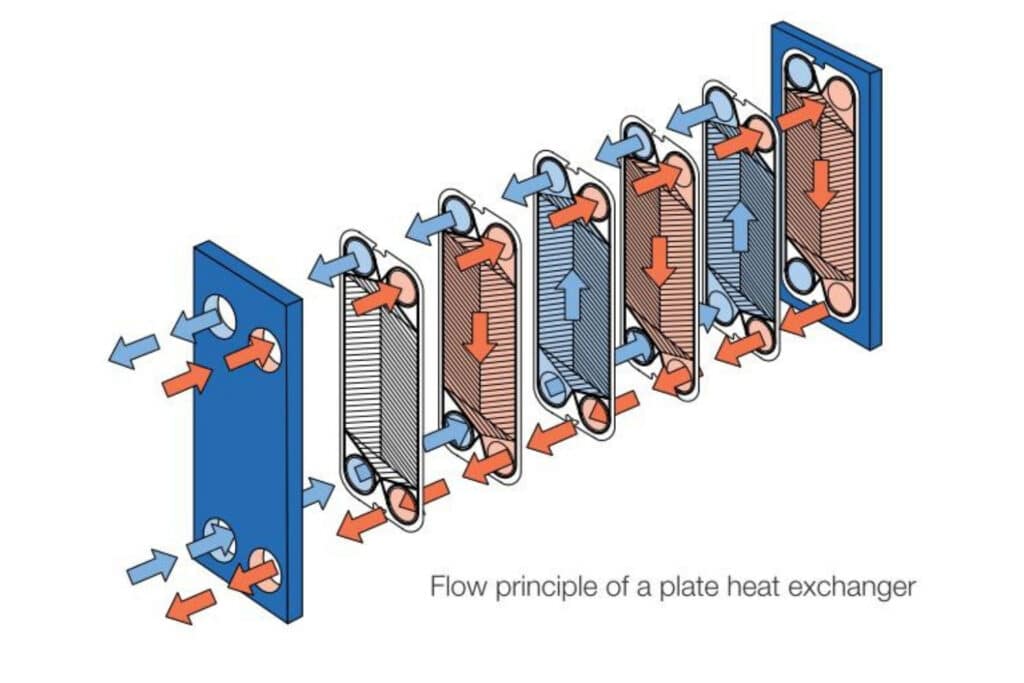

Besides tubular walls, heat exchangers may also be built with plate walls. This image shows a typical plate and frame heat exchanger in the expanded view.

Hot fluid and cold fluid are directed to alternative chambers formed by the plates. Heat is transferred from the hot side to the cold side for each plate. These plates are stamped with precise shape geometry.

The heat transfer walls are corrugated to increase surface area and to enhance the heat transfer coefficient. This allows more heat transfer walls to be packed in a given space than a tubular heat exchanger.

Increase Heat Flow

Heat transfer coefficient is the reversal of heat resistance between the two fluids. In detail, heat has to flow from the hot fluid to the hot surface of the plate wall, go through the wall to the cold surface, and flow from the cold surface to the cold fluid.

When heat flows between a liquid and a solid surface, the more turbulence in the fluid, the higher the heat transfer coefficient is. Corrugated walls increase the turbulence in the fluid and increase the heat transfer coefficient. In other words, the corrugation not only increases the areas but also increases heat flow per unit area.

Gaskets are used around the edges of the plates to prevent fluids from escaping when the plates are assembled with bolts to tighten them together. The plate edges may also be fully welded together.

Either way, there are a lot more gaps to be closely compared to a tubular heat exchanger, such as the solar exchanger. The fluids may have high pressure and or temperature.

That will make the sealing of these gaps more challenging. Nevertheless, a heat exchanger has to be built to handle the fluids safely and rated only to be operated under specific pressure and temperature limits.

Conclusion

Heat exchanger works by its internal walls to allow heat to pass from hot fluid to cold fluid efficiently. A heat exchanger may have a lot of tubular or plate walls packed in it. A heat exchanger also needs to handle the fluids safely, especially when the fluids are at high temperatures or high pressure.