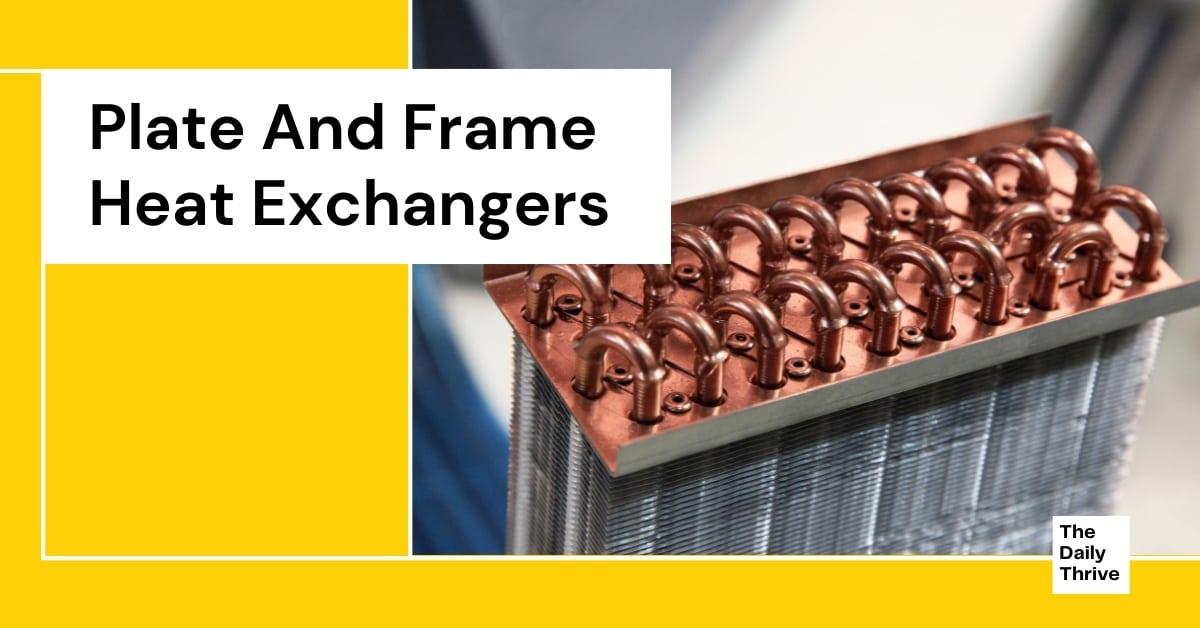

Plate and frame heat exchangers use metal plates to transfer heat between two fluids. The plates are stacked in a pile with gaskets in between to separate the plates and to direct the flow. A frame and two thick plates are usually on the ends of the pile to hold the plates tight to create the seal against the gaskets.

Plate And Frame Heat Exchangers Constructions

The plate and frame heat exchanger (PHE) was invented by Dr. Richard Seligman in 1923. A plate and frame heat exchanger consists of a frame in which closely spaced metal plates are clamped between a head and follower(or float head).

The plates have corner ports and are sealed by gaskets around the ports and along the plate edges. A double seal forms pockets open to the atmosphere to prevent product and service liquids from mixing in the rare event of leakage past a gasket.

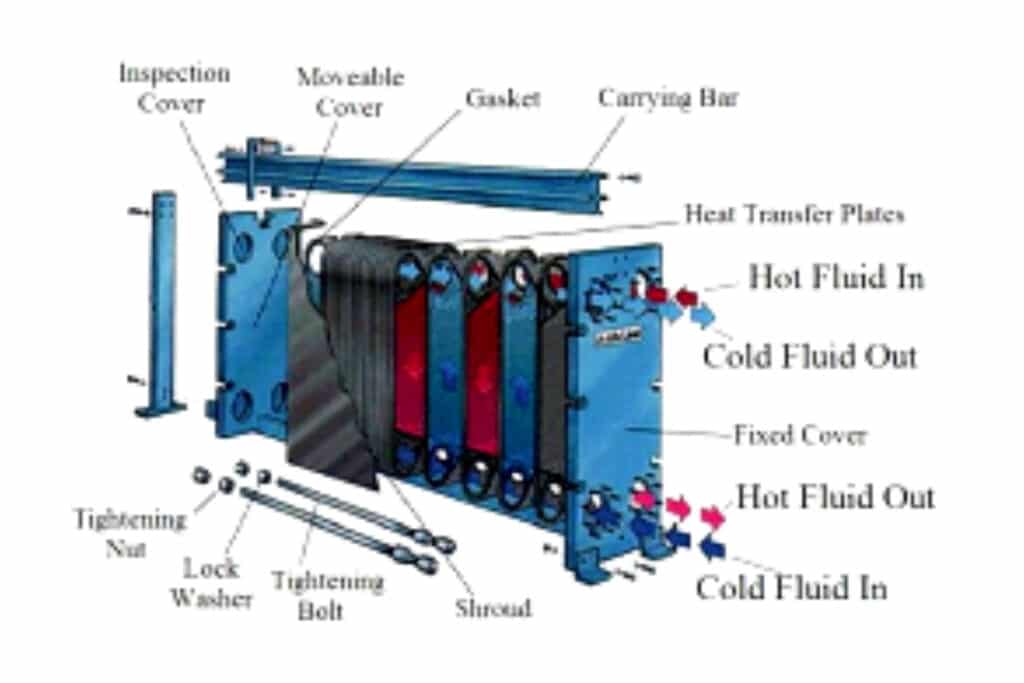

The hot fluid goes in from an upper port through every other channel between the plates and flows out at a lower port. The cold fluid goes in from a lower port through the rest of the channels between the plates and flows out at an upper port.

Gaskets are used around the edges of the plates to prevent fluids from escaping when the plates are assembled with bolts to tighten them together. The plate edges may also be fully welded together.

Either way, there are a lot more gaps to be closely compared to a tubular heat exchanger, such as the solar exchanger. The fluids may have high pressure and or temperature. That will make the sealing of these gaps more challenging.

Nevertheless, a heat exchanger has to be built to handle the fluids safely and rated only to be operated under specific pressure and temperature limits.

- Gasketed so that both sides of the plate can be cleaned.

- Semi-welded for clean fluid such as refrigerants on the welded side.

- Fully-welded plate heat exchangers to handle corrosive environments and high-temperature

- Brazed plate heat exchangers can be an extremely small footprint.

- Fusion bonded plate for aggressive liquids and high corrosion resistance.

Advantages

The major advantage of a plate and frame heat exchanger over a tubular heat exchanger is that the plates may be much thinner and tighter than the tubes and therefore transfer more heat for the same amount of metal weights and space used.

A plate heat exchanger is always in a single pass and, therefore, can be most effective when the two-fluid temperature difference is very small. It may cool fluid to a lower temperature than the coolant’s outlet temperature, which is impossible for two or more to pass heat exchangers.

Disadvantages

Because of the tighter construction and uneven flow passes, plate and frame heat exchanges are most susceptible to fouling and not easy to open for cleaning. Numerous gaskets with large areas also make leaking more likely, especially for high pressure and oscillating temperatures.

Plate And Frame Heat Exchangers Application

Plate and frame heat exchangers have a wide application, for example, to cool lubricating oil from machines, cool wastewater, heat water for the beverage industry, etc. The types of industries that can utilize plate and frame heat exchangers are also very broad, for example, petrochemicals, paper mills, food and beverage factories, shipping, etc., which generally require cooling/heating where the machine works continuously and for a long time.