Bryant furnace error codes serve as crucial diagnostic tools, helping homeowners and technicians quickly identify and address potential issues with their heating systems. These codes, unique to Bryant furnaces, offer detailed insights into the system’s functioning, enabling efficient troubleshooting. This comprehensive guide will delve into the meanings of various Bryant furnace error codes, including the significance of yellow light codes.

Understanding Bryant furnace error codes is vital before embarking on any troubleshooting steps. These codes could indicate various issues, from a faulty gas valve, clogged filter, or malfunctioning pressure switch.

To interpret these codes effectively, refer to the owner's manual or consult the comprehensive list provided here.

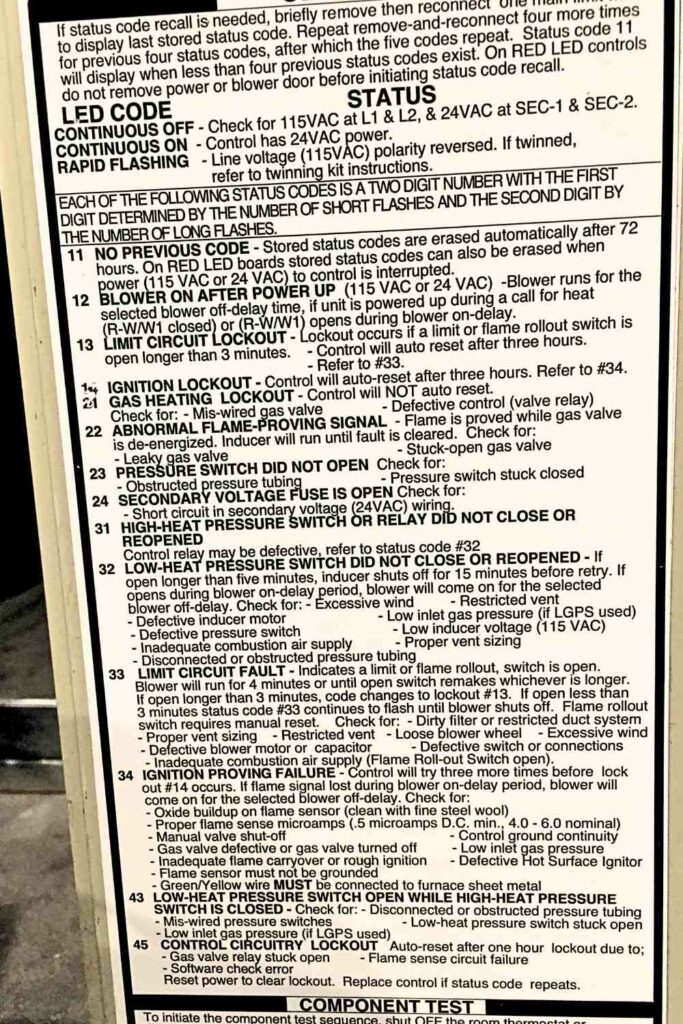

LED Error Codes

Bryant furnaces utilize an intuitive LED indicator system to signal operational statuses. For instance, a Green LED4 On signifies low-heat operation. At the same time, a Red LED1 On indicates the furnace is in emergency heat mode. Understanding these indicators can be the first step in troubleshooting any issues your furnace might encounter.

| LED Indicator | Meaning |

|---|---|

| Green LED4 On | Furnace operating in low heat. |

| Red LED1 On | Furnace in emergency heat mode. |

| Red LED2 Flashing | Reversed line voltage polarity. |

| Red LED2 On | Microprocessor malfunction. |

| Yellow LED3 On | Furnace operating in high heat. |

Bryant Error Codes: Detailed Breakdown

Each error code, ranging from Code 11 to Code 45, signifies a specific issue. For example, Code 22 indicates an abnormal flame-proving signal, hinting at potential gas valve problems. This article will delve into each code, outlining potential causes and appropriate troubleshooting steps.

| Error Code | Description |

|---|---|

| Code 11 | No fault code – stored codes auto-erase after 72 hours. |

| Code 12 | Blower activation post-power-up. |

| Code 13 | Limit circuit lockout. |

| Code 14 | Ignition lockout. |

| Code 21 | Gas heating lockout. |

| Code 22 | Abnormal flame-proving signal. |

| Code 23 | Pressure switch issues. |

| Code 24 | Secondary voltage fuse issues. |

| Code 25 | Model selection/setup error. |

| Code 31 & 32 | High and low-heat pressure switch issues. |

| Code 33 | Limit circuit fault. |

| Code 34 | Ignition proving fault. |

| Code 43 | Low-heat pressure switch issues. |

| Code 45 | Control circuitry lockout. |

Common Bryant Furnace Errors and Troubleshooting Tips

Certain error codes are more prevalent than others. This section will focus on these common errors, offering practical DIY troubleshooting tips. It will also guide homeowners in identifying situations that necessitate professional intervention, ensuring that more complex issues are handled safely and effectively.

Error Code 12: Blower Operation Anomaly

This code is typically triggered when the Bryant furnace blower operates under unusual conditions. Specifically, it occurs when the blower activates after the furnace has powered up, either because the unit is powered up during a call for heat (thermostat demanding heat with R-W/W1 closed) or when the thermostat call for heat opens during the blower’s on-delay period.

DIY Troubleshooting:

- Check Thermostat Settings: Confirm that the thermostat settings are correct. An incorrect setting might inadvertently cause the blower to activate.

- Inspect Thermostat Wiring: Look for any loose or damaged wiring between the thermostat and the furnace. Such issues can lead to improper blower operation.

- Power Cycle the Furnace: Try turning off the furnace at the breaker, wait a few minutes, and then turn it back on. This can reset the system and potentially resolve transient issues.

- Evaluate Blower Motor and Relay: Investigate the blower motor and its relay for any signs of malfunction or unusual noise. These components can sometimes cause the blower to run continuously or unexpectedly.

Error Code 13: Limit Circuit Lockout

This code is triggered if a limit or flame rollout switch is open for an extended period.

DIY Troubleshooting:

- Check for any obstructions in the airflow that might cause overheating.

- Inspect the filters and replace them if they are dirty.

- Ensure all registers in the home are open and not blocked.

- When to Call a Professional: If the problem continues after checking these areas or if you cannot locate the limit switch, it’s time to seek professional help.

Error Code 22: Abnormal Flame-Proving Signal

The flame is proved while the gas valve is de-energized.

DIY Troubleshooting:

- Investigate for a leaky or stuck open gas valve.

- Make sure the inducer is running properly.

- When to Call a Professional: Professional diagnosis and repair are recommended due to the complexity of this issue, especially related to the gas valve.

Error Code 24: Secondary Voltage Fuse Issues

Indicates a short circuit in the secondary voltage wiring.

DIY Troubleshooting:

- Check for any obvious wiring shorts.

- Inspect the fuse and replace it if necessary.

- When to Call a Professional: If the furnace fuse blows immediately or you cannot locate the short, professional electrical diagnostics are needed.

Error Code 31: High-Heat Pressure Switch Issues

The error code 31 indicates the high heat pressure switch did not close or reopen.

DIY Troubleshooting:

- Check the vent sizing to ensure it’s appropriate.

- Inspect the pressure switch wiring for any faults.

- Ensure the combustion air supply isn’t restricted, and the condensate drain isn’t plugged.

- When to Call a Professional: If you’re unsure about the vent sizing or wiring, contacting a technician is safer. Also, professional diagnostics may be necessary if issues persist after checking the mentioned areas.

Error Code 33: Limit Circuit Fault

Indicates a limit or flame rollout switch issue or that the furnace operates in high-heat-only mode.

DIY Troubleshooting:

- Reset the flame rollout switch if it has a manual reset feature.

- Check for proper installation of the limit switch and its gasket.

- Inspect the blower wheel for any looseness or damage.

- When to Call a Professional: Professional assistance is advisable if the switch requires frequent resetting or if you’re uncertain about the internal components’ condition.

Error Code 34: Ignition Proving Fault

This code occurs when the control system fails to detect a flame.

DIY Troubleshooting:

- Clean the flame sensor gently using fine steel wool.

- Check the manual gas valve to ensure it’s in the open position.

- Verify the gas valve’s operational status and gas pressure.

- When to Call a Professional: If cleaning the flame sensor doesn’t solve the issue or you’re unsure about handling gas valve components, it’s best to call a technician.

What Is Error Code 86 On Bryant Geothermal Furnace?

Error Code 86 on a Bryant geothermal furnace typically relates to a communication fault with the equipment’s thermostat. This error indicates that the furnace’s control board is not receiving a signal from the thermostat, which is essential for the system to operate correctly. Here’s a brief overview of how to approach this issue:

Troubleshooting Error Code 86 on a Bryant Geothermal Furnace

- Check Thermostat Connections: Ensure the thermostat is correctly wired to the furnace. Loose or incorrect wiring can often be the cause of communication issues.

- Inspect Thermostat Functionality: Test the thermostat to see if it’s functioning properly. This can be as simple as adjusting the temperature to see if there is any response from the furnace.

- Power Cycle the System: Sometimes, resetting the entire system can resolve communication glitches. Turn off the power to the thermostat and the furnace, wait a few minutes, and then power them back on.

- Examine the Control Board: The control board in the furnace is responsible for communication with the thermostat. Look for any visible signs of damage or malfunction.

- Evaluate Wiring and Connections: Check all related wiring and connections for any signs of damage, wear, or loose connections.

- Software or Firmware Updates: If your thermostat and furnace system use software or firmware, ensure they are updated to the latest versions.

- Environmental Checks: Make sure there are no environmental factors (like extreme temperatures or moisture) that could be affecting the thermostat or furnace electronics.

Preventive Measures and Regular Maintenance for Bryant Furnaces

Regular maintenance is key to ensuring the longevity and efficiency of your Bryant furnace. By adhering to a routine maintenance schedule, you can significantly reduce the frequency of error codes and ensure your furnace operates optimally. Here are some essential tips for maintaining your Bryant furnace:

- Regular Filter Replacement

- Frequency: Check and replace your furnace filters every 1-3 months, depending on usage and the type of filter.

- Benefits: Clean filters improve air quality and furnace efficiency while reducing strain on the system.

- Annual Professional Inspections

- Scheduling: A certified HVAC technician inspects your furnace annually, ideally before the heating season.

- Scope: The technician should check all components, including the heat exchanger, burners, blower motor, and thermostat, for any wear or malfunction.

- Cleaning and Dusting

- Regular Cleaning: Keep the furnace and surrounding area clean and dust-free. Accumulated dust can impede airflow and efficiency.

- Component Focus: Pay attention to cleaning the blower blades and the furnace interior, as dust accumulation can lead to overheating and system failure.

- Checking the Ventilation System

- Inspection: Inspect the vent system for blockages, leaks, or corrosion.

- Clearance: Ensure no debris or obstruction around the intake and exhaust vents to maintain proper airflow.

- Monitoring Thermostat Performance

- Testing: Test your thermostat periodically to ensure it’s accurately reading and regulating the temperature.

- Upgrade: Consider upgrading to a programmable or smart thermostat for better efficiency and control.

- Listening to Unusual Noises

- Awareness: Be alert to any unusual sounds from your furnace, like banging, whistling, or grinding, which could indicate mechanical issues.

- Response: Address any strange noises promptly to prevent further damage.

- Checking the Condensate Drain

- Inspection and Cleaning: Ensure the condensate drain is not clogged. A blocked drain can cause water damage and affect humidity levels.

- Ensuring Proper Gas Pressure and Flame

- Gas Pressure: Have a professional check the gas pressure to ensure it’s at the correct level for your furnace model.

- Flame Inspection: The burner flame should be blue with a small yellow tip. A mostly yellow flame indicates a potential problem.

- Checking Electrical Connections

- Tightness and Wear: Inspect electrical connections for tightness and wear. Loose connections can cause malfunctions and are a safety hazard.

- Upkeep of Moving Parts

- Lubrication: Periodically lubricate moving parts like motors and bearings to reduce friction and wear.

- Keeping a Maintenance Log

- Documentation: Keep a record of all maintenance activities, including professional inspections, repairs, and any error codes.

Understanding and addressing Bryant furnace error codes are essential for maintaining an efficient and safe heating system. This guide provides detailed explanations and troubleshooting steps for each error code, helping homeowners and technicians resolve common furnace issues quickly.

Always consult the owner’s manual or a professional technician when dealing with furnace errors to ensure safety and accuracy. This guide is intended for informational purposes and should be used in conjunction with professional advice.